THE REPORT OF EXPERT TWIN VISIT

I. INTRODUCTION

Follow the proposed work plan and visit schedule of twinning program phase II between Phnom Penh Water Supply Authority as expert twin organization, and Nampapa Nakkhone Luang as recipient twin, under financial support of Asian Development Bank, the team of four experts of expert twin has visit NPNL for carrying out the remaining works. The objective of this visit mainly concern to the fields of NRW reduction, to provide the OJT to NPNL’s staff on DMAs monitoring, and observe the feasibility of energy saving in water treatment plant that could be assisted NPNL to reduce their expenditure on power consumption. This progress report will be covered the remarkable transformation and progressive improvement by NPNL related to expert recommendation since last visit of twinning phase I, the activities and results during the visit, request and recommendation for self-improvement of NPNL and proposed target for the next visit of recipient twin.

II. Self-improvement Progress

As recommendation by expert in report of diagnostic survey and further, during last visit of recipient twin in PPWSA, we will summary the progress of work plan implemented by NPNL since last visit of twinning program phase I.

After retirement of the former Director General, Mr. Khampeuy has been promoted since the March 2012 as new General Manager of NPNL. On the beginning of his mission, the new General Manager has updated the organization structure for proper management. The new structure almost following PPWSA structure, in case of duties and tasks of NPNL are quite similar to PPWSA.

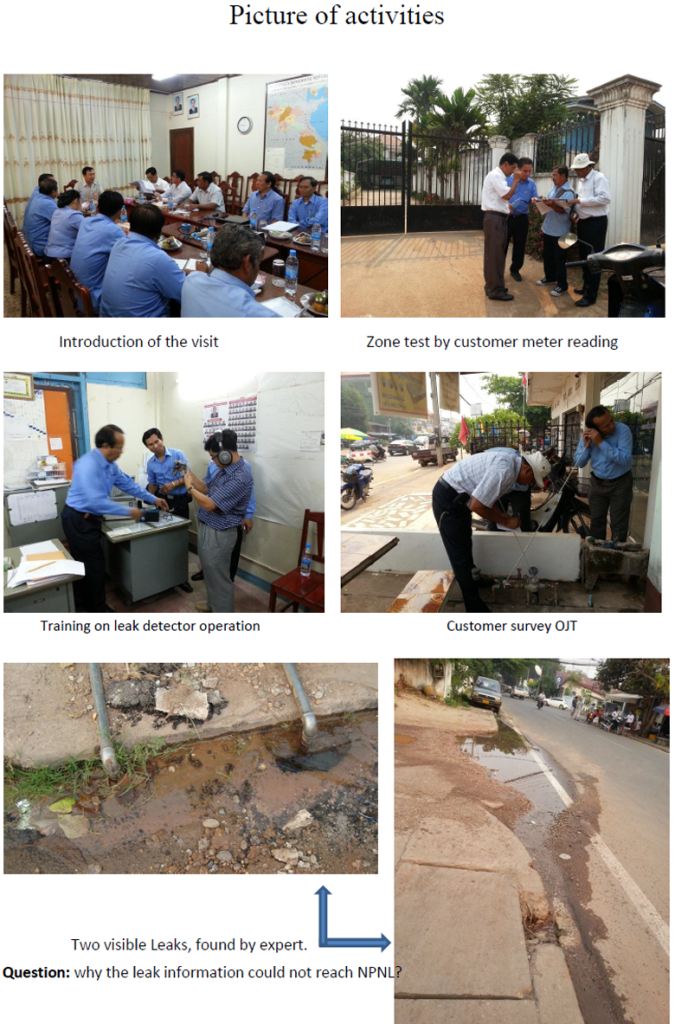

• The creation of two teams with seven staffs for block distribution control is the initiative prevention to invisible leak, providing OJT and experience by PPWSA on two pilot areas, established since phase I of the twinning program.

•Following recommendation, NPNL has created the bulk meter control team with 4 staffs, responsible for reading and check to big customers meters monthly.

III. The Visit Progress

• We have carried out 72 hours test on 27 March 2013 full day, to identify the NRW ratio of each zone. After the test, we found that the loss in zone no 1 approximately 36.90%. For both zone, NPNL has followed the expert guide to complete the last reading on 06 April 2013. Now NPNL has completed and confirmed the final test result of both zone on 06 April 2013: the total loss approximately 37% in zone 1 and 28% in zone 2.

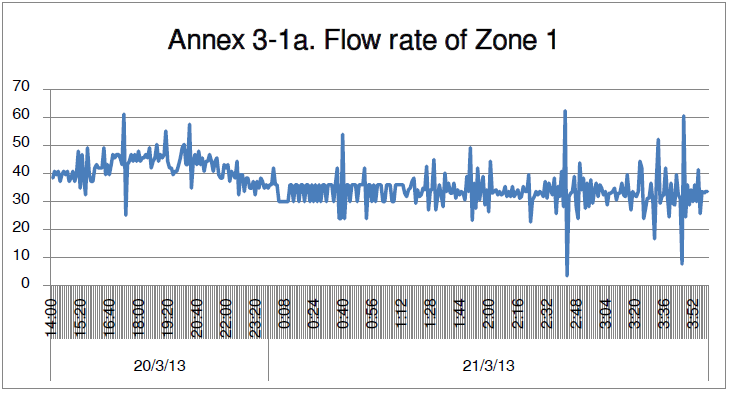

• Minimum flow test have been implemented and analysis for suspect leaks. By analysis result of 24 hours flow data, we found the minimum night flow in zones No 1too high, around 45m3 per hour, compare to average flow rate 33 m3 per hour.

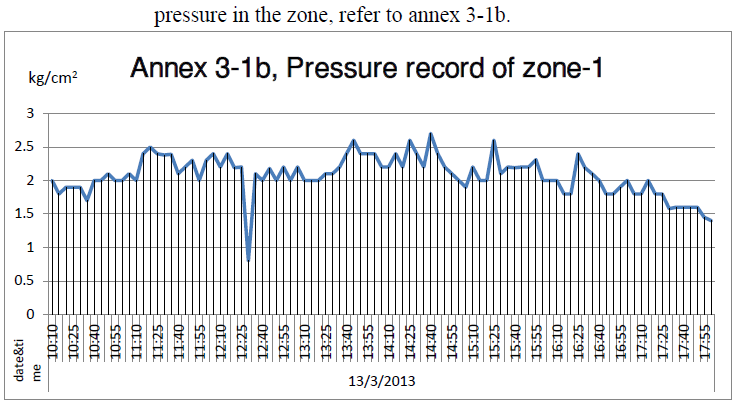

NPNL staff has informed to expert about on-ground tanks of each customer house, reserved for water interrupted case. After a spot survey house to house around the pilot zone with NPNL staffs, we found that 90% of customers have a roof tanks or on-ground tanks, but most of tanks filled water at daytime, cause of sufficient pressure in the zone, refer to annex 3-1b.

With information and the above chart, we have to consider on two reasons of high minimum flow: firstly, it may cause from invisible leaks and secondly, it also may cause by water flow filled the tanks at night. But the first idea is priority for further investigation. o Leak detection and customer survey has carried out by the team under OJT. After detection of 15 customers in zone-1, we catch the leak noise in five difference locations. In case of disturbance by hard concrete, the NPNL staff could not continue digging the trench by hand, and experts have to leave Vientiane on the next morning, therefore we ask NPNL staff to continue trench opening and report us later what is the noise coming from.

Recommendation

1- The loss ratio measurement with duration of one day test can be high risk of error. Therefore, NPNL team has to continue the reading test within 10 days on both zones. According to the benchmark index dated 27 March 2013, the next reading should be on 06 April, 2013. We offer NPNL to complete the task and send us the result of last reading for finalize the actual situation. The last result has mentioned the above.

2- DMA control team has to continue leak detection for whole zone. Through experience, we suspect many invisible leaks in the zones.

3- The expert have found two visible leakages which is one of them located inside the pilot zone and the other located out of pilot area. We suggest NPNL to take action on controlling their hotline information procedure or to the leaks repair action.

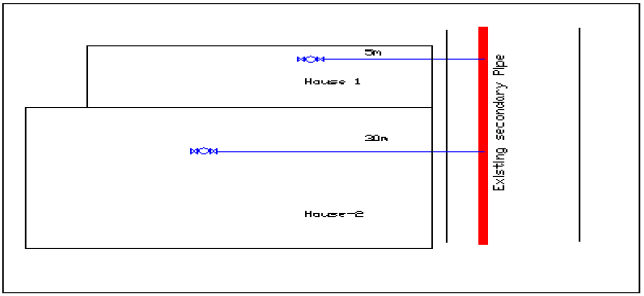

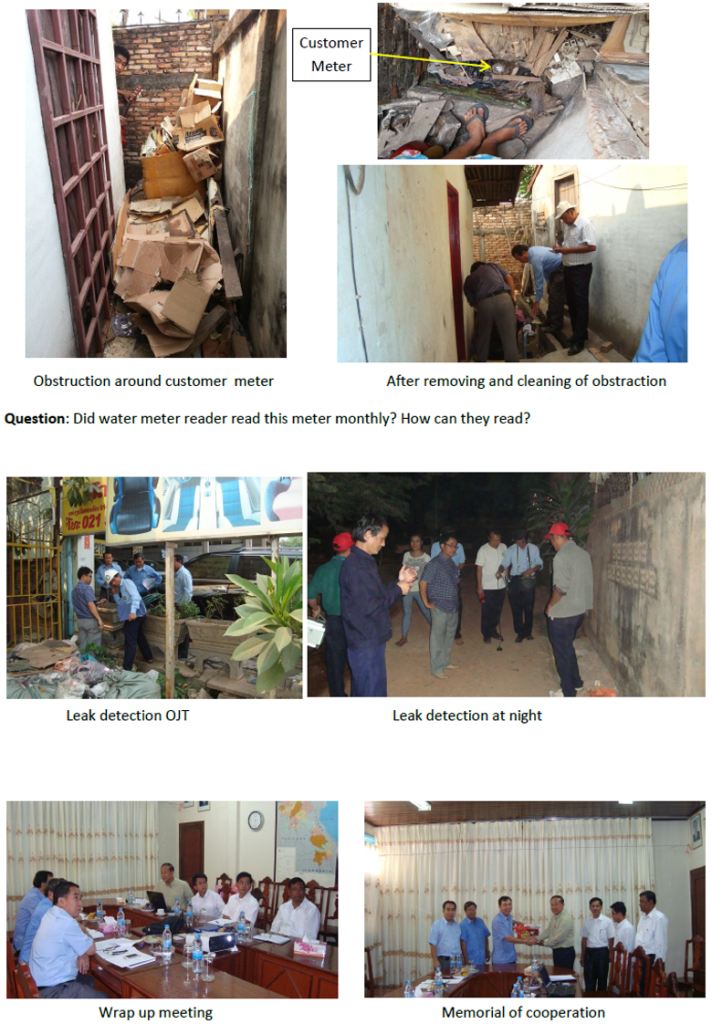

4- We have found abnormal house connection inside the zone. NPNL have to limit the location of customer water meter. By our experiences, meter should be located nearest to the front fence or front house wall. There are two things of trouble can be cause to NPNL: firstly, loss by leakages in the service pipe between fence and meter, secondly, customer may easily abuse with illegal by-pass,

5- We would like to request NPNL manager to consider on providing of incentive policy to the leak repair and DMA control team. The outcome of encouraging to the staffs is increasing their motivation.

6- During the meeting, we have been informed by NPNL General Director on countermeasure to the reading error. In the opinion of expert after customer survey, the error of reading mostly cased from desk reading. We have found the abnormal index compare to the last bill index, and many defective water meters inside the zone with covered by dirty soil for long time. The problem solving to this case, NPNL has to set up Meter Reading Procedure as a guidebook, than provide reading control system to the meter readers. PPWSA can assist on the guidebook template during NPNL visit to PPWSA, for references.

Recommendation

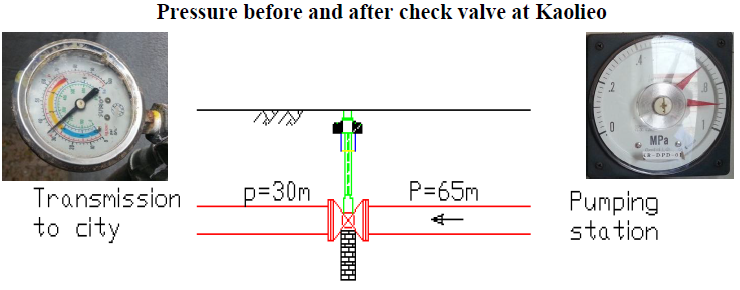

1- This case was in PPWSA in 2002 after completion of construction of new Chroychangwar water treatment plant. The energy consumption of this treatment plant was 320w/m3 of treated water. The solution has done by PPWSA in 2007 for reduction of power consumption is pump replacement, following the study recommendation by outsource consultant, we change only pump equipped with existing motor. After completion of the project with 47m total head of new pumps, instead of 65m, the energy consumption of Choychangwar has dropped from 320w/m3 to 250w/m3. The same case was with Chamcarmorn water treatment plan. It means 20% of power consumption has been saved. The total budget for pump replacement was around USD 200,000.

2- Firt of all, NPNL has to consider on specific future pressure in their network, than calculate the designed pressure of the new pump. If they can reduce 15m of the pump head, from 65m to 50meters, the consumption expected to drop around 15%. The sample calculation of benefit for only Chinaimo water treatment plant, by using of 2012 data, as shown below:

o Actual production in 2012 = 4 million.m.cu

o Actual power consumption = 3.20 million kw

o If reduce 15% of power consumption = 480,000 kw

o The tariff of energy for industry = 720 Lao kip per kw

o Saving amount = 480,000 kw x 720kip = 345,600,000kip = 45,000USD/ year

o If, the project cost = 150,000 USD

o Depreciation time = 3.5 year

NPNL may save more amounts of energy, if the replacement covers the other treatment plants.

3- The SCADA system combine with Variable Speed Drive, proposed for automatic operation of pumps, will also a part of energy saving. PPWSA has equipped their treatment system with SCADA. Byt NPNL has to consider the first priority project between pump replacement and SCADA system.

IV. Preparation of Next Visit

During wrap up meeting, we have discussed on objective and selected six nominees for the next visit of recipient to PPWSA. The objective of next visit concerning to:

1- Energy saving and pump replacement in Chroychanwar project

2- DMA management and leak detection activities

3- Customer management and meter reading procedure, guidance

4- Water meter management

Related to the above objective, the nominee of next visit will be:

1- Viengthouoy Vannarath Mr. – Team leader

2- Southin Khiangsombath Mr. – Chief of Chinaimo WTP

3- Anouvong Dethoudom Mr. – Chief of Saisetha branch office

4- Bounhom Douangchantha Mr – Chief of meter management section

5- Bounpasong Phochalath Mr. – Chief of planning section

6- Southano Sisombath Mr. – Chief of DMA section

V. Conclusion:

With revision and addition of this report, director general of PPWSA and NPNL have discussed on general management additionally, especially on meter reading error, than they have agreed fully with the result of this visit. NPNL top manager has promised to follow step by step to the above recommendation.

NPNL top manager has mention that the expert twin has provided the importance knowledge and experience to his staff on the field of NRW, than the key survey result on energy saving will be consider as priority and looking for detail design.

Khmer

Khmer